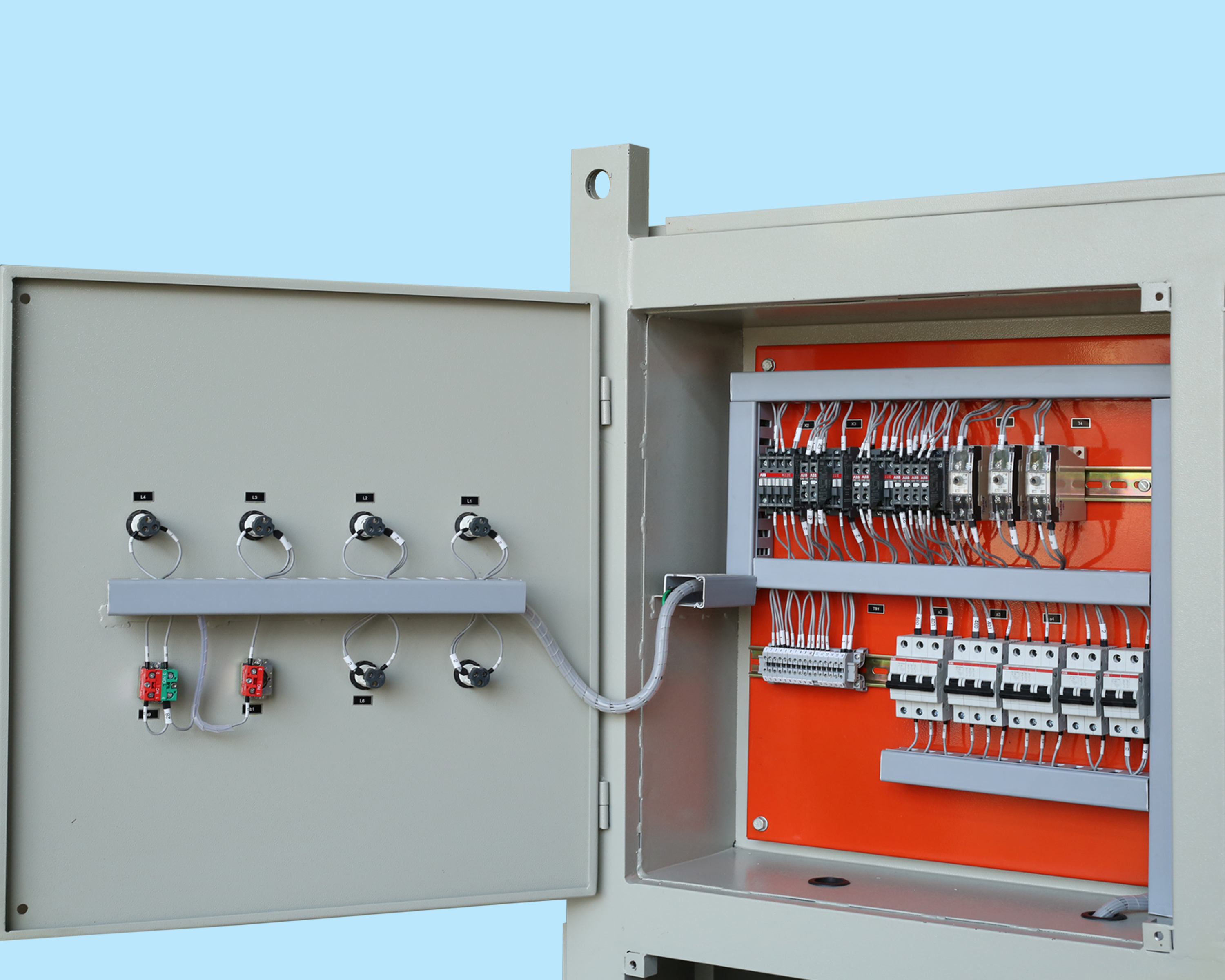

Slip Dependent Resistance Starter (Rotor Controller) with slip regulator (Dynamic Buffer resistance) For Slip ring Induction motors. Back

In running some applications like Cane Fibrizor, Cane Cutter, Cane Chopper, Crushers , Mixers etc. experiences frequent kick loads / variable load due to uneven raw material feeding. This leads to overloading of the motor due to insufficient motor torque & causes nuisance tripping due to over current, which affects the process & results production loss.

In running some applications like Cane Fibrizor, Cane Cutter, Cane Chopper, Crushers , Mixers etc. experiences frequent kick loads / variable load due to uneven raw material feeding. This leads to overloading of the motor due to insufficient motor torque & causes nuisance tripping due to over current, which affects the process & results production loss.

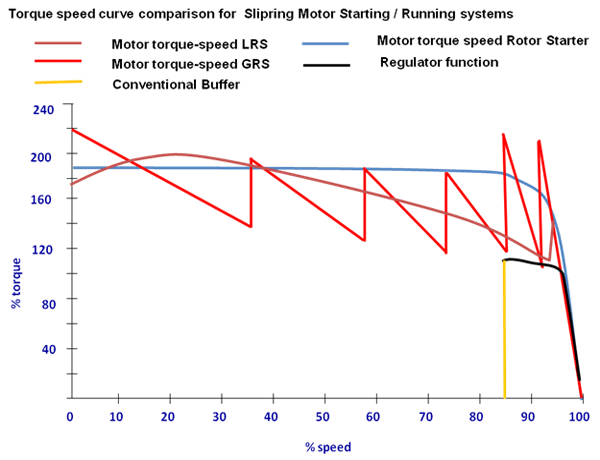

To avoid this, 15% fixed conventional buffer resistance is kept in the Motor Rotor circuit to deliver the high torque & to limit current kicks.

This is useful when the motor is loading more than 100% for short time. When there is rated load or load less than the actual rating of motor then there is no need of 15% conventional Buffer Resistance in the Motor Rotor circuit. This resistance will create continuous power loss in the form of heat loss.

Slip Regulator / Dynamic Buffer(DB) offers variable Resistance in the Rotor circuit due to slip dependent Resistance technology. When there is kick load / over load, then Slip Regulator offers Resistance instantaneously depending on slip at that load to its maximum value (upto 12 - 15%) & when the load is less than 100% of rated capacity or equal to rated capacity, then Slip Regulator offers 3 to 4% Resistance.

This reduced value of Resistance during under load will help to save the power as compared to conventional Buffer Resistance.

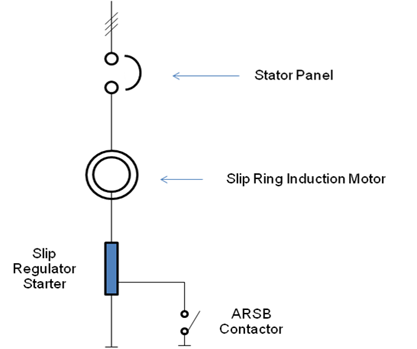

In Rotor Resistance Starter / Controller the part of resistance is kept in the Motor Rotor circuit continuously as a Slip Regulator / dynamic buffer to provide the required running torque to the applications which are experiencing the variable loads (like Crusher, Fibrizor in sugar Industries.) Depending on overloading pattern the speed tends to reduce which increases the slip frequency results to increase in resistance. As load goes down the slip frequency reduces results to reduce the resistance.

The Slip regulator is designed in such a way that the resistance offered by it is frequency dependent.

When the motor starts from zero speed the rotor frequency is equal to supply frequency and the Slip regulator resistance is maximum (like rotor starter). And in running the rotor frequency is low (depending on slip) and the Slip regulator resistance minimum. This value is decided as follows :-

The Slip regulator is designed in such a way that the resistance offered by it is frequency dependent.

When the motor starts from zero speed the rotor frequency is equal to supply frequency and the Slip regulator resistance is maximum (like rotor starter). And in running the rotor frequency is low (depending on slip) and the Slip regulator resistance minimum. This value is decided as follows :-

RSR = R0 + Ar fr where

RSR = Slip regulator resistance at any

frequency

R0 = Residual Slip regulator DC resistance

(very low value –typically 3%)

Ar = Resistance amplification factor

fr = Rotor frequency

When the motor runs at higher speed the rotor frequency is low (typically 3-4 %)

and the Slip regulator resistance is minimum. This value is decided as follows :-

The rotor voltage of the slipring motor is governed by the following equation.

VR = s x RVss

where VR = Rotor voltage at slip s

s = per unit slip

RVss = Rotor voltage at standstill

In Running, with the increase in load the motor slip increases so the rotor voltage. The running resistance has to be increased to boost the motor torque & avoid the current kicks.

RRS/Ph = [(RVss/1.73) / (RA x p.u.Torque)]

where RRS/Ph = equivalent star resistance of Slip regulator

in ohms

RVss = Rotor Line voltage at standstill in Volts (rated).

1.73 = Line to phase conversion factor

RA = Rotor current in amps (rated).

p.u.Torque = Motor torque desired at standstill per unit value

The variation of Slip regulator resistance with change in motor speed (change in rotor frequency)

is automatic and stepless.

Range: 37 KW/415 V to 6,000 KW/3.3 KV, 6.6 KV, and 11 KV.

Salient Features:

• Slip dependent Resistance provides automatic resistance variation during acceleration & running.

• Low Starting current.

• High starting torque.

• Built in Slip regulator contactor.

• No moving parts & stepless cutting of Resistance.

• No maintenance.

Applications:

Sugar industry - Fibrisors, Cutters, Levellers & applications which requires high starting & running torque.